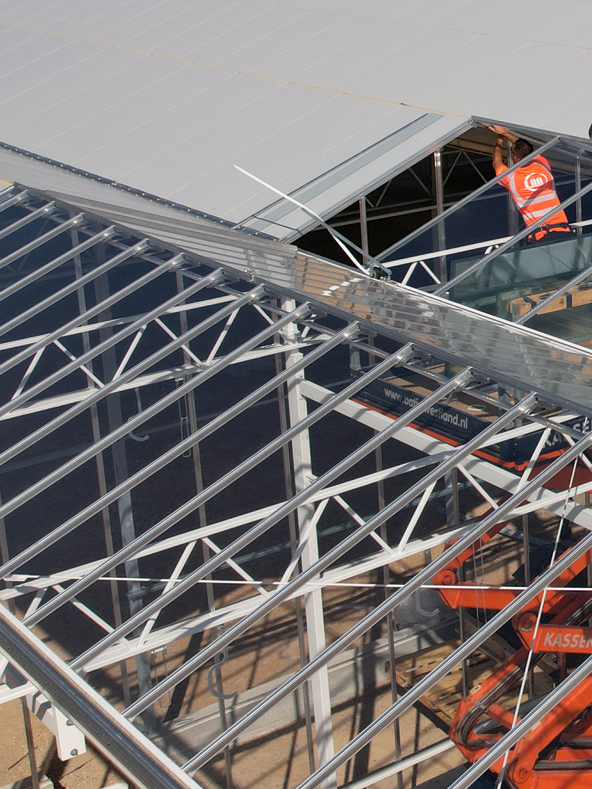

The choice for a aluminum greenhouse over steel is due to the weight and strength of the material and the possibility to create detailed profiles with it. The core function of the aluminium roof system is to hold glass in place and to discharge rainwater as gutter. In many cases a pvc gasket is applied to ensure a water and wind tight seal between the glass and aluminium. The aluminum roof- and gutter systems are calculated and engineered with great care. Just like the steel structure, the aluminium system is carried out as light and as strong as possible. Greenhouse Constructive engineering is done with the Dutch “The City of Glass” which enables the aluminium greenhouse to withstand the external forces according to industry regulations.

Aluminium Greenhouse System

Aluminium Greenhouse System

Aluminium Gutters

As described earlier, the aluminium greenhouse gutter does not only collect the rain and snow, but it fulfils a crucial constructive role. This ingenuous system cares for the strength in the gutter-direction of the greenhouse. It significantly reduces the amount of material required to construct the greenhouse.

Next to this, the gutter also collects condensation water from the glass on the inside of the aluminium greenhouse. If required by regulation or just for good practice, this can be discharged separately from the rainwater. This condensation water function of the gutter prevents water dripping on the crops, which can cause damage in the form of burn spots or physical damage.

As greenhouses serve an agricultural / horticultural function, the aluminium used is non-anodised aluminium. Aesthetically non-anodised aluminium is not the most pleasing, but is the systems do serve their function.

More information about aluminium in greenhouses?

More information about aluminium in greenhouses?

FAQ

A greenhouse is made watertight primarily through the use of an aluminum roof system that serves multiple functions, including holding the glass in place and discharging rainwater through gutters. To ensure a water- and wind-tight seal between the glass and aluminum, a PVC gasket is often applied. This meticulous engineering of the aluminum roof and gutter systems aims to keep the structure as light and as strong as possible while adhering to industry regulations.

Aluminum profiles contribute to a self-supporting roof system that minimizes light interception, a key feature for promoting plant growth. These profiles are designed to prevent glass breakage and leakage while also offering options for various covering materials like sandwich panels and polycarbonate. Additional benefits include ease of installation for features like insect netting, making it a future-proof choice. Overall, aluminum provides a combination of strength, efficiency, and versatility, making it a preferred material for the super-structure of Dutch greenhouses.

These gutters connect two perpendicular trusses at their ends. Their role is not just limited to water drainage; they also contribute to the structural integrity of the greenhouse, particularly in the gutter direction. By doing so, they help to reduce the amount of material required for constructing the greenhouse, contributing to both efficiency and sustainability.

The aluminum used in the construction of Dutch greenhouses is non-anodized because the primary focus is on functional aspects of the material, rather than its aesthetic appeal. Anodizing aluminum can add to the cost and may not offer significant functional benefits in the context of a greenhouse, which primarily serves agricultural or horticultural purposes. Non-anodized aluminum fulfills the structural and functional requirements effectively, making it a practical choice for this specific application.